Bucket Elevator

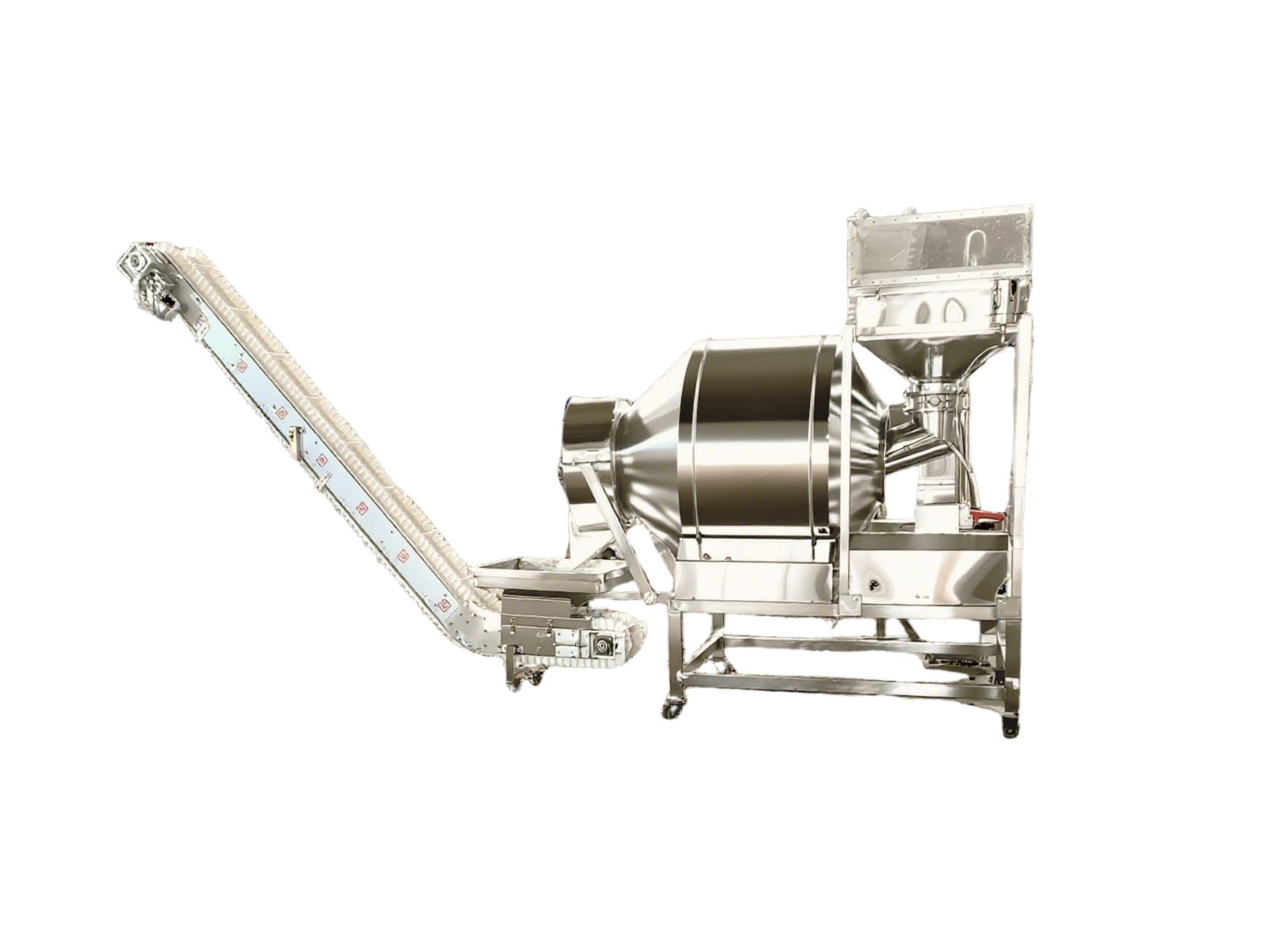

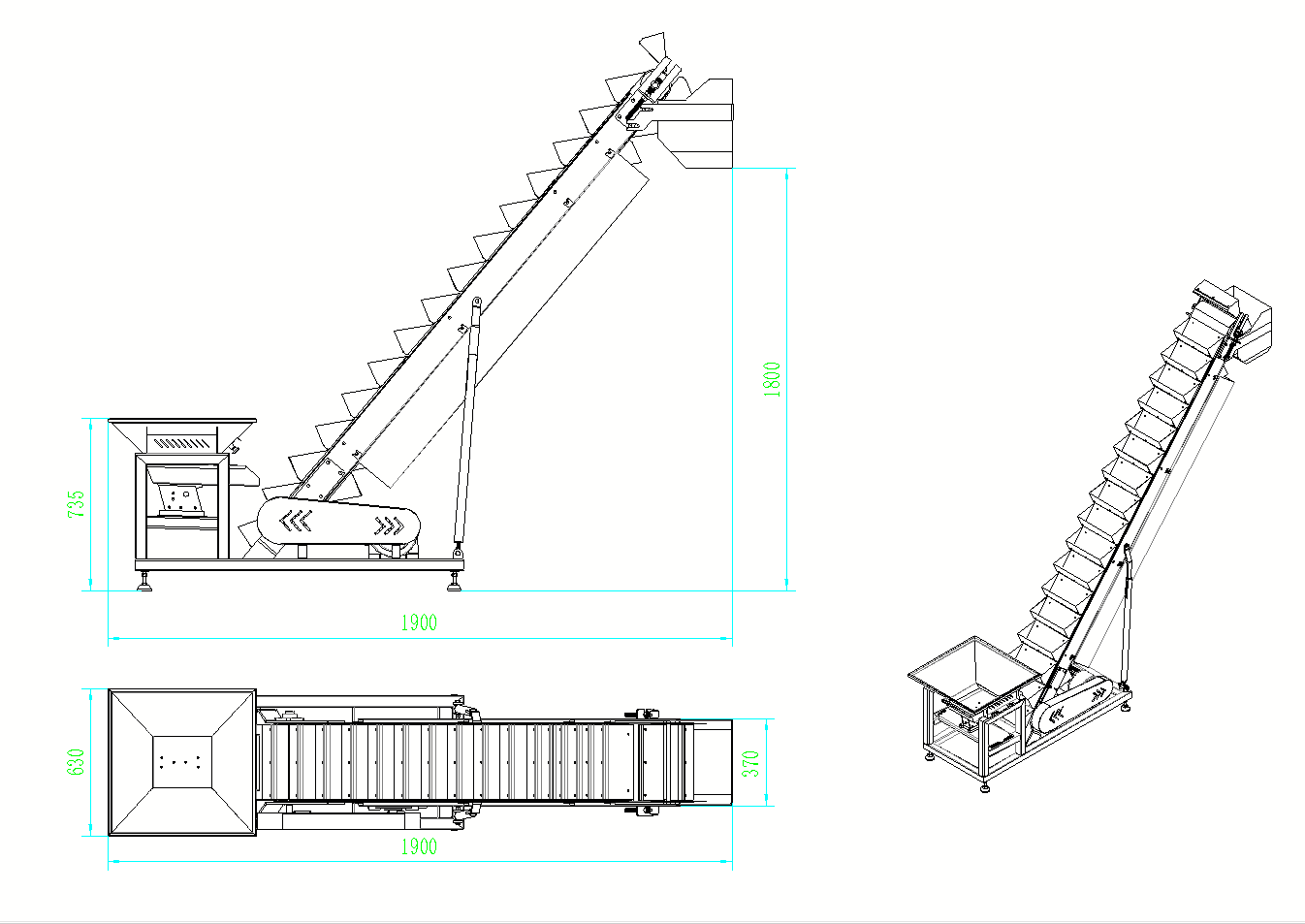

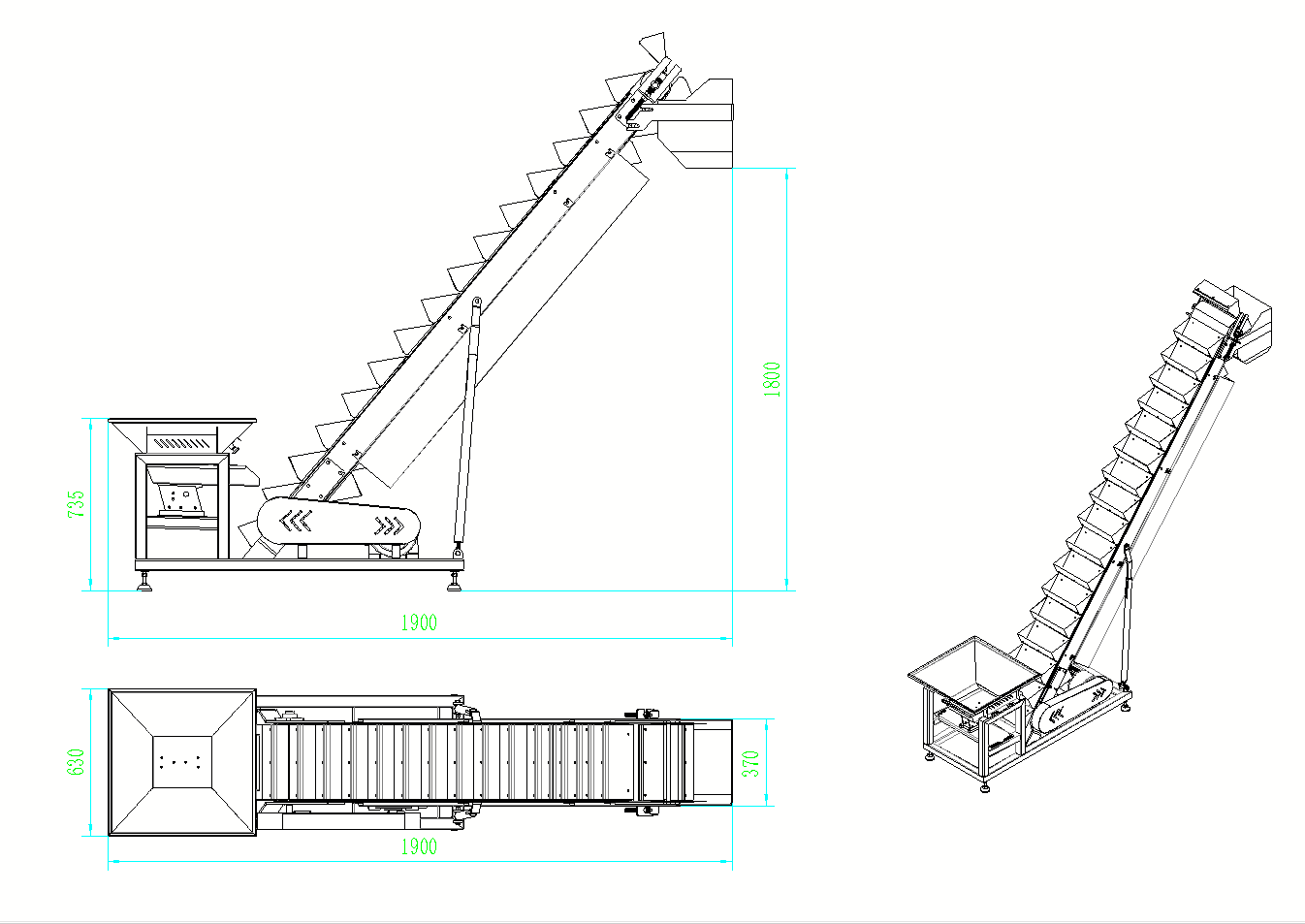

Stainless steel bucket elevator designed for lifting various powder and granular materials. Compatible with packaging machines for automatic material level tracking and feeding, or standalone use in various applications.

- Stainless steel construction (except motor, bearings, frame)

- Convenient maintenance with long service life

- Thickened steel plate casing with superior rigidity

- High temperature capability up to 250°C

- Single and dual channel configurations available

- Smooth, reliable operation with low noise

Product Introduction

The Stainless Steel Bucket Elevator series can lift various powder and granular materials and can be paired with packaging machines to achieve material level tracking and automatic feeding, or used independently in other applications. Except for the motor, bearings, and frame, all other components are made of stainless steel.

Performance Features

- Easy Maintenance: Convenient maintenance with long service life and reliable operation

- Robust Construction: Thickened steel plate casing provides superior rigidity and durability

- High Temperature Resistance: Can transport materials at temperatures up to 250°C

- Flexible Configuration: Mid-section casing available in single channel and dual channel configurations

- Smooth Operation: High lifting height with smooth, reliable operation and low noise

- Enhanced Capacity: Improved models provide 30% higher lifting capacity than conventional designs

- Superior Chain: Low alloy steel forged chain with carburizing and quenching treatment for excellent tensile strength and wear resistance

Applicable Materials

Food Products:

Cookies, gummy candies, marshmallows, mini steamed buns, pancakes, chicken essence, milk tea, jelly, pearl fruit, milk tea powder, shrimp strips, potato chips, rice noodles, dumplings, chocolate, peanuts, coffee, sugar, nuts, candy beans, sunflower seeds, pistachios, walnuts, almonds, rice, millet, and various granular and powdered food products.

Chemical Products:

Plastic granules and powders (PP, PE, PS), activated carbon, preservatives, additives, screws, nuts, and other chemical materials requiring lifting and conveying operations.

Product Details

The production line includes a complete material handling process: feeding → grinding → mixing → lifting → packaging. Each process is carefully designed to ensure production efficiency and product quality.

Equipment Working Principle

The production line operates through a series of interconnected processes: material feeding → grinding → mixing → lifting → packaging. Advanced crushing technology ensures uniform particle size, precision mixing systems guarantee consistent quality, automated lifting and conveying systems reduce manual handling, and intelligent packaging systems with quality control.

1V1 Custom Service

We provide professional 1V1 custom services, designing equipment technology according to customers' specific needs. Our engineering team has rich industry experience and can tailor the most suitable solutions for customers.

Scope of Application

Our bucket elevator is designed to serve a wide range of industries with diverse material processing needs. We provide comprehensive powder processing solutions that meet the specific requirements of each industry sector.

Company Strength Introduction

Zhengzhou PinChuang Machinery is a professional manufacturer specializing in customized powder processing solutions. With over 10 years of experience, we provide complete production lines, including pulverizers, mixers, elevators, dust collectors, and packaging machines.

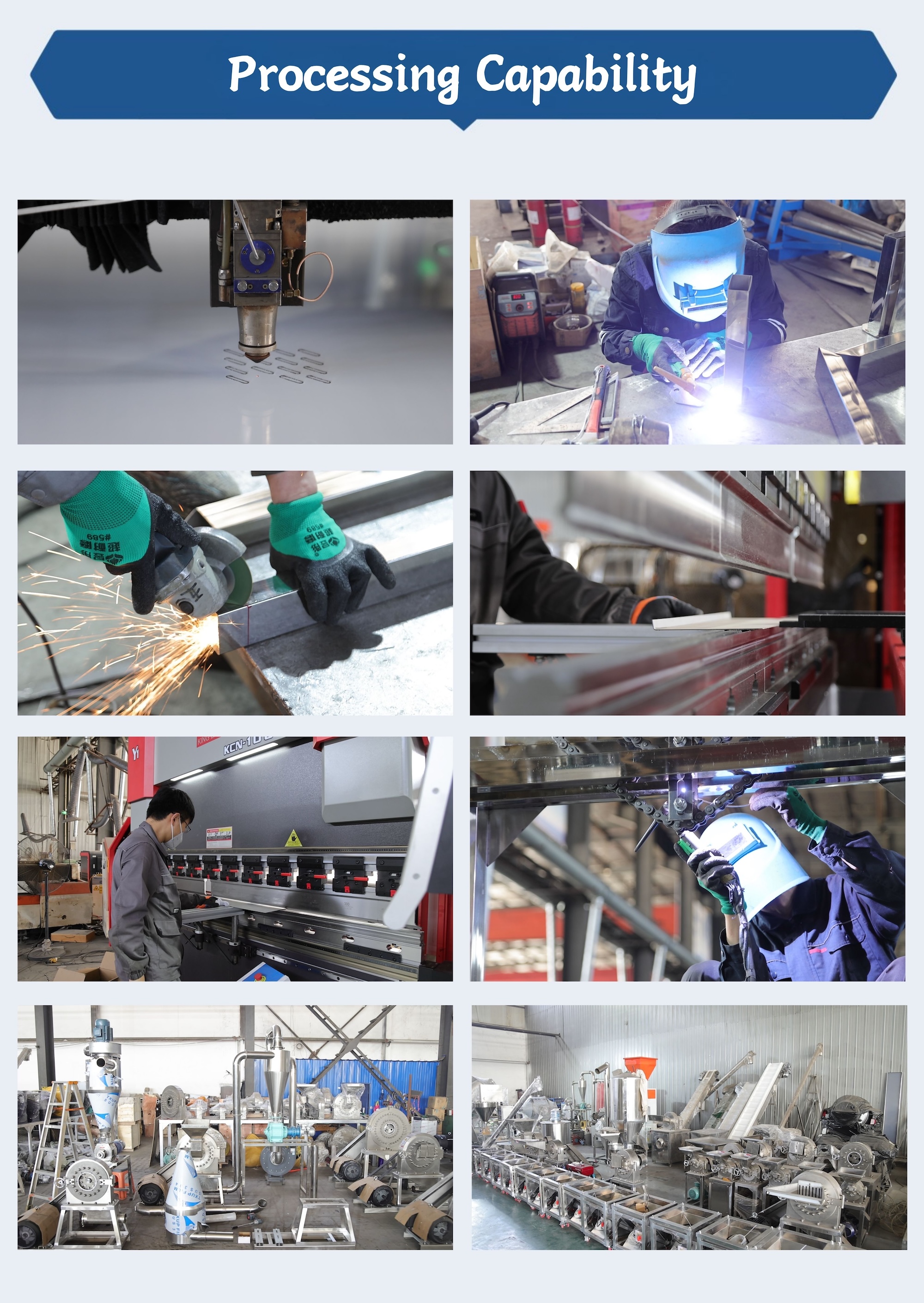

Our factory is located in Henan, China, covering more than 3,000 square meters, and equipped with advanced CNC cutting, welding, and polishing facilities. We serve industries such as food processing, herbal medicine, spices, and grain milling with efficient and durable machinery.

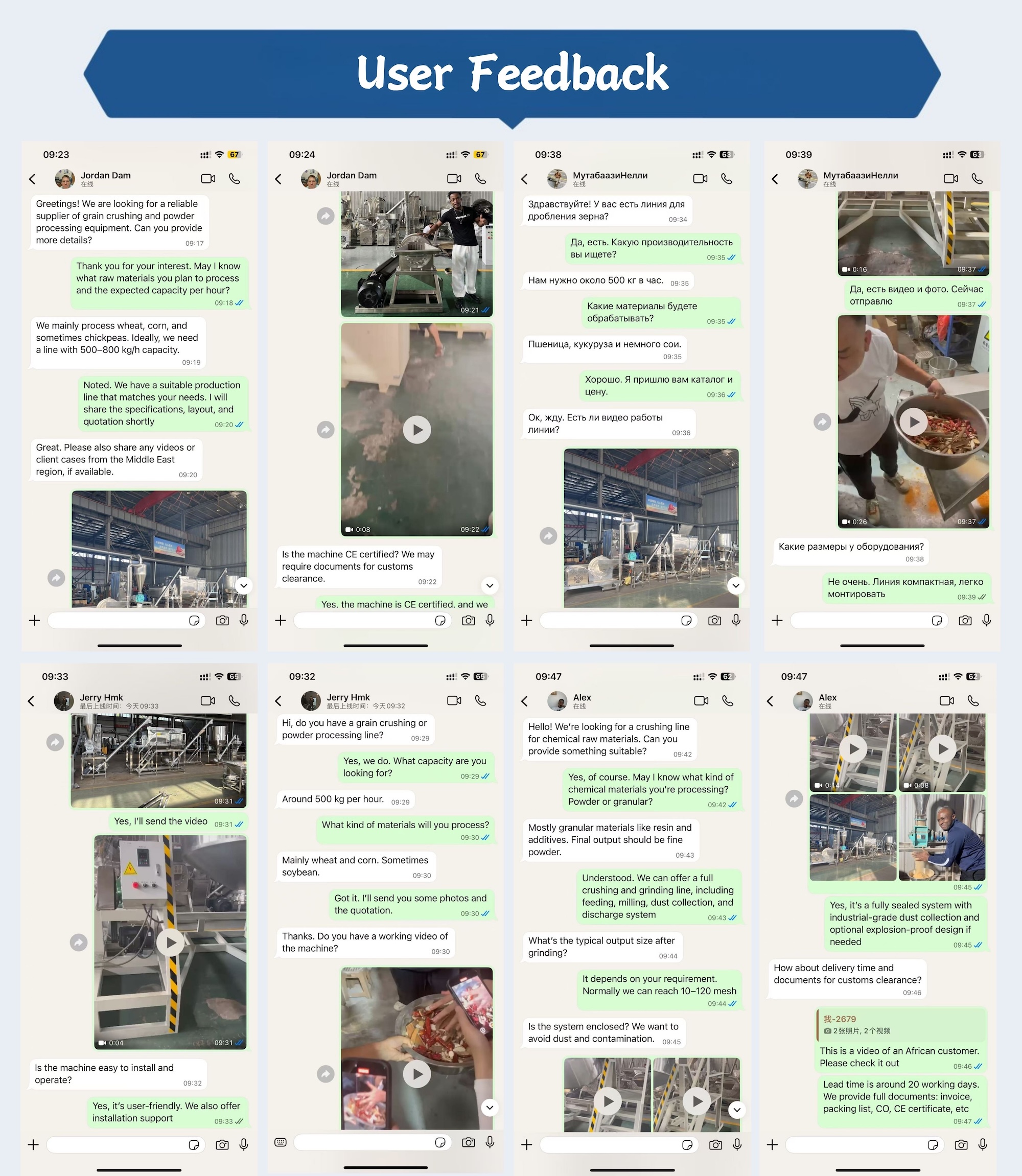

User Feedback Photos

Real feedback from customers on our products and services, demonstrating our professional standards and service quality.

Logistics & Equipment Installation and Debugging

We provide complete logistics and delivery services. Professional teams are responsible for equipment installation and debugging to ensure normal operation of equipment.

Company Processing Capability

We have advanced processing equipment and professional technical teams to provide customers with high-quality custom products.

Certificate Photos

We have multiple industry certifications and certificates to ensure product quality and service standards.