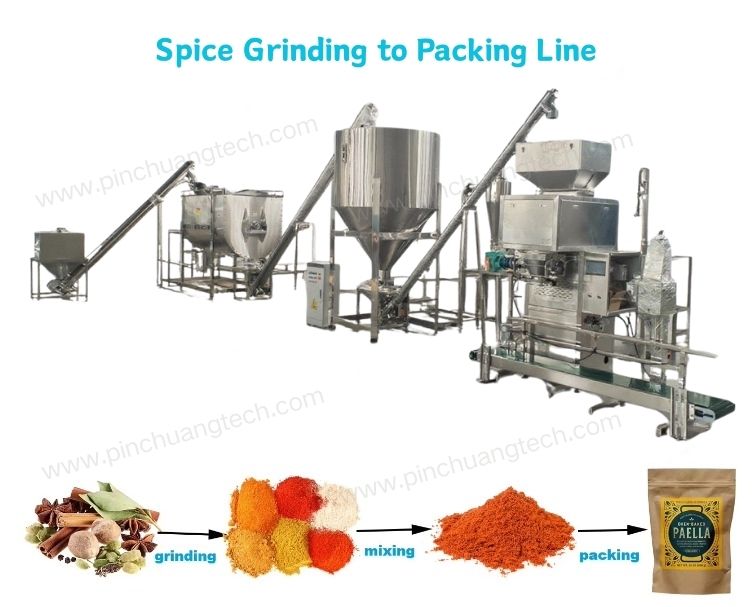

Spice Grinding, Mixing & Packing Production Line - Complete Integrated Solution

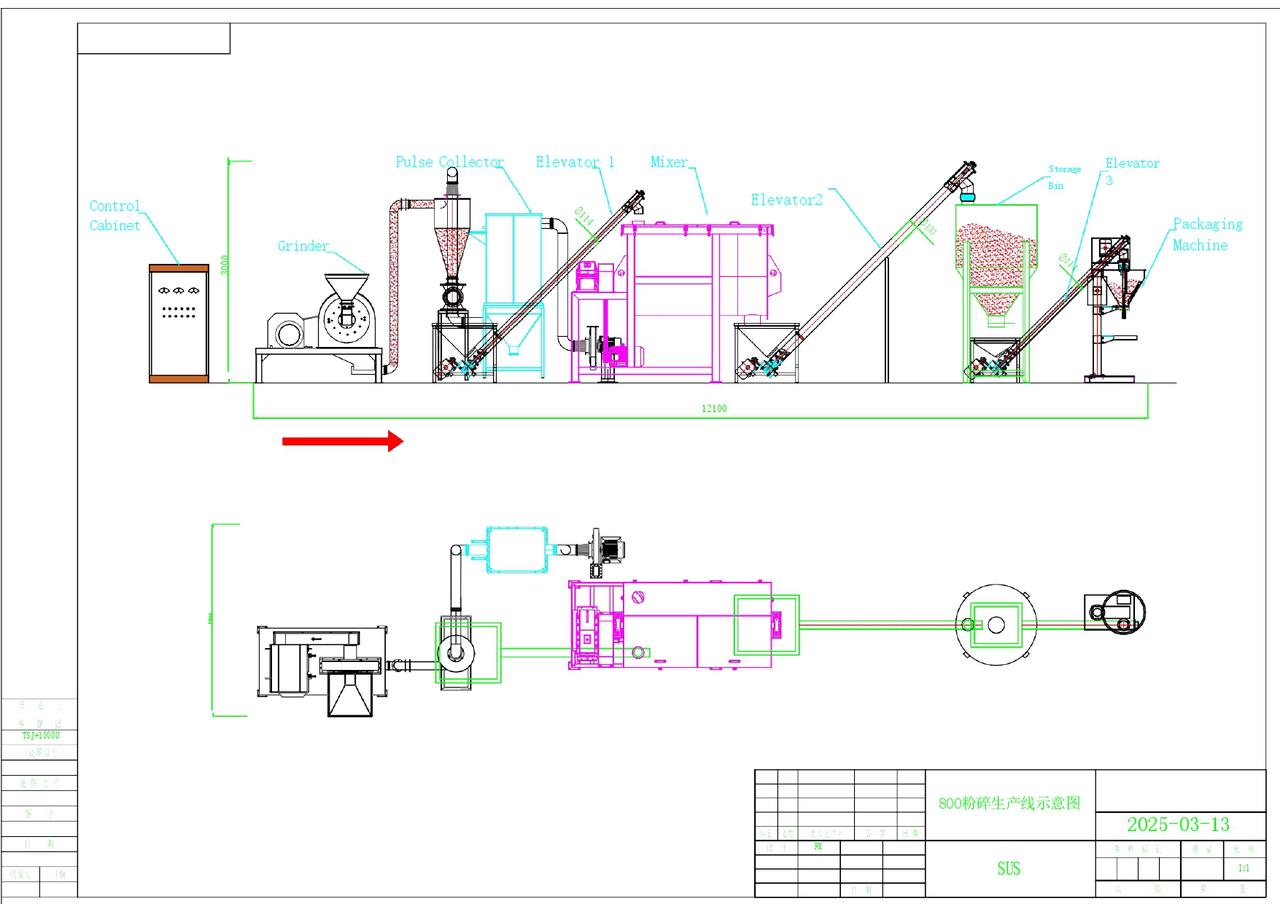

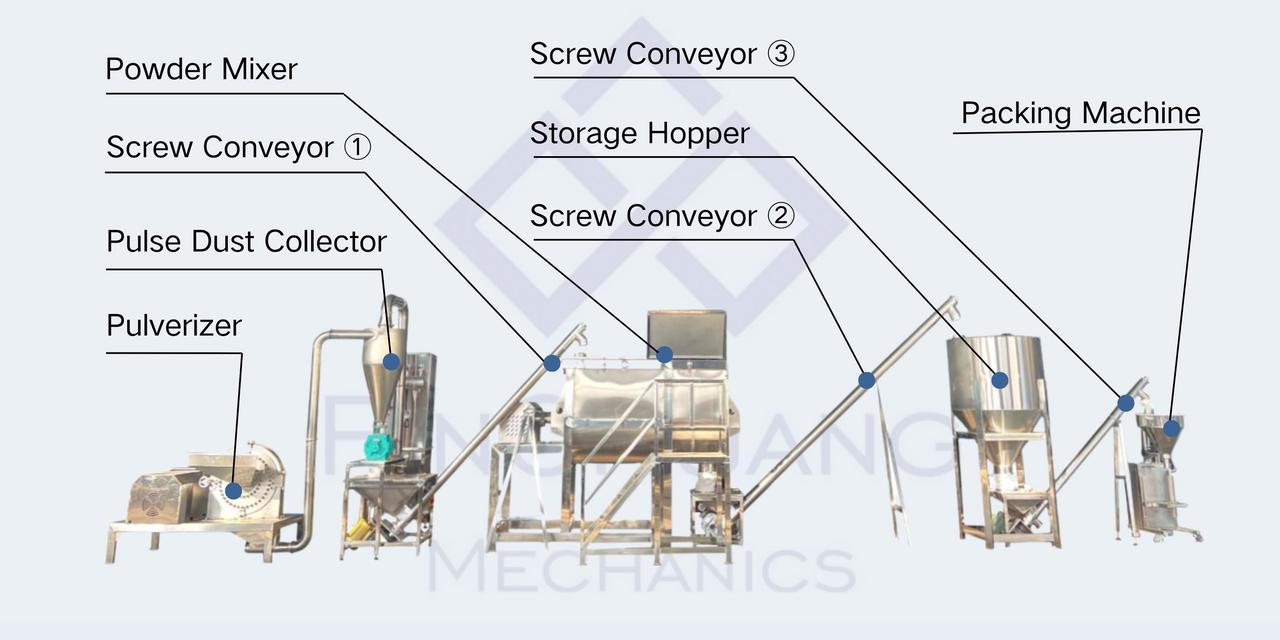

The Spice Grinding, Mixing & Packing Production Line is a complete integrated solution designed for large-scale processing of chili, Sichuan pepper, and various spices. This comprehensive system combines grinding, dust collection, mixing, conveying, and automatic packing into one continuous process, maximizing efficiency while maintaining product quality and workplace safety standards.

System Overview

Fully Integrated Design:

The production line seamlessly connects all processing stages, from raw material feeding through final packaging, eliminating manual handling and reducing contamination risks while maximizing throughput efficiency.Modular Construction:

Each processing unit is independently designed and can be customized based on specific product requirements, production capacity needs, and facility constraints, allowing for flexible configuration and future expansion.Automated Control:

Central PLC control system manages the entire production process, ensuring consistent product quality, optimal resource utilization, and comprehensive data logging for quality assurance and traceability.

Primary Processing Stages

Raw Material Handling

- Cleaning System: Removes foreign matter, stones, and damaged materials

- Feeding Conveyor: Controlled material feed rate with load monitoring

- Storage Hoppers: Intermediate storage with level sensors and discharge controls

- Pre-treatment: Optional steaming, roasting, or conditioning as required

Grinding & Size Reduction

- High-Efficiency Pulverizers: Multiple grinding units for different fineness requirements

- Cooling Systems: Prevent heat damage to heat-sensitive spices and volatile oils

- Sieving Units: Ensure consistent particle size distribution and quality control

- Recirculation System: Oversized particles automatically returned for re-grinding

Environmental & Safety Systems

Dust Collection & Control

- Primary Cyclone Separators: Remove coarse dust particles and reduce air volume

- Pulse Bag Filters: High-efficiency filtration achieving 99.9% dust removal

- Explosion Prevention: Inert gas systems and explosion relief valves for safety

- Air Quality Monitoring: Continuous monitoring of workplace air quality parameters

Hygienic Design Features

- Food-Grade Materials: All product contact surfaces in 304/316 stainless steel

- Sanitary Construction: Smooth surfaces, rounded corners, and easy-clean design

- CIP Systems: Clean-in-place capabilities for thorough sanitization

- Contamination Prevention: Positive pressure systems and sealed construction

Blending & Mixing Operations

Precision Blending

- Recipe Management: Automated weighing and dosing of multiple ingredients

- Mixing Technology: High-efficiency ribbon blenders for uniform distribution

- Quality Control: In-line sampling and testing for consistency verification

- Batch Tracking: Complete traceability from raw materials to finished products

Specialized Mixing Options

- Spice Blend Formulations: Custom mixing for specific flavor profiles

- Oil Addition Systems: Controlled addition of essential oils and oleoresins

- Coating Applications: Uniform distribution of anti-caking agents and preservatives

- Temperature Control: Heated or cooled mixing for specific product requirements

Packaging & Final Processing

Automated Packaging Systems

- Multi-Format Capability: Bags, pouches, bottles, and bulk containers

- Weight Control: Precision weighing systems for accurate filling

- Sealing Technology: Heat sealing, ultrasonic welding, or mechanical closure

- Quality Inspection: Weight checking, metal detection, and visual inspection

Packaging Options

- Consumer Packaging: Small retail packages from 10g to 1kg

- Foodservice Packaging: Medium packages from 1kg to 25kg

- Industrial Packaging: Bulk bags and containers up to 1000kg

- Custom Packaging: Specialized formats for specific market requirements

Production Capabilities

Capacity & Efficiency

- Processing Capacity: 500kg/hour to 5000kg/hour depending on configuration

- Product Range: Chili powder, pepper blends, curry powders, mixed spices

- Fineness Options: 20-200 mesh with consistent particle size distribution

- Automation Level: 90% automated operation with minimal manual intervention

Quality Standards

- Food Safety: HACCP, FDA, and international food safety compliance

- Quality Assurance: ISO 9001 quality management systems

- Traceability: Complete batch records and ingredient tracking

- Testing Protocols: Microbiological, chemical, and physical testing capabilities

Technology Integration

Smart Manufacturing Features

- IoT Connectivity: Real-time monitoring and remote diagnostics

- Data Analytics: Production optimization through data analysis

- Predictive Maintenance: Equipment health monitoring and maintenance scheduling

- Energy Management: Optimized power consumption and utility usage

Process Optimization

- Recipe Development: Laboratory and pilot-scale testing capabilities

- Process Validation: Comprehensive validation protocols for new products

- Continuous Improvement: Ongoing optimization based on production data

- Technical Support: 24/7 technical assistance and troubleshooting

The complete spice production line represents the pinnacle of modern food processing technology, delivering consistent high-quality products while maintaining the highest standards of safety, hygiene, and environmental responsibility.

Need More Information?

Our professional team will provide personalized recommendations

Send Email Inquiry WhatsApp Inquiry