Storage Silo

Professional storage silo for powder, grain, feed, and chemical materials. Features durable stainless steel construction with customizable capacity and cone-bottom design for smooth material discharge.

- Stainless steel / carbon steel optional construction

- Customizable volume (0.5m³ – 50m³)

- Cone-bottom design for smooth discharge

- Suitable for powder, granules, grain, and chemicals

- Easy to integrate with conveyors & packaging lines

- Anti-corrosion and food-grade material options

Product Introduction

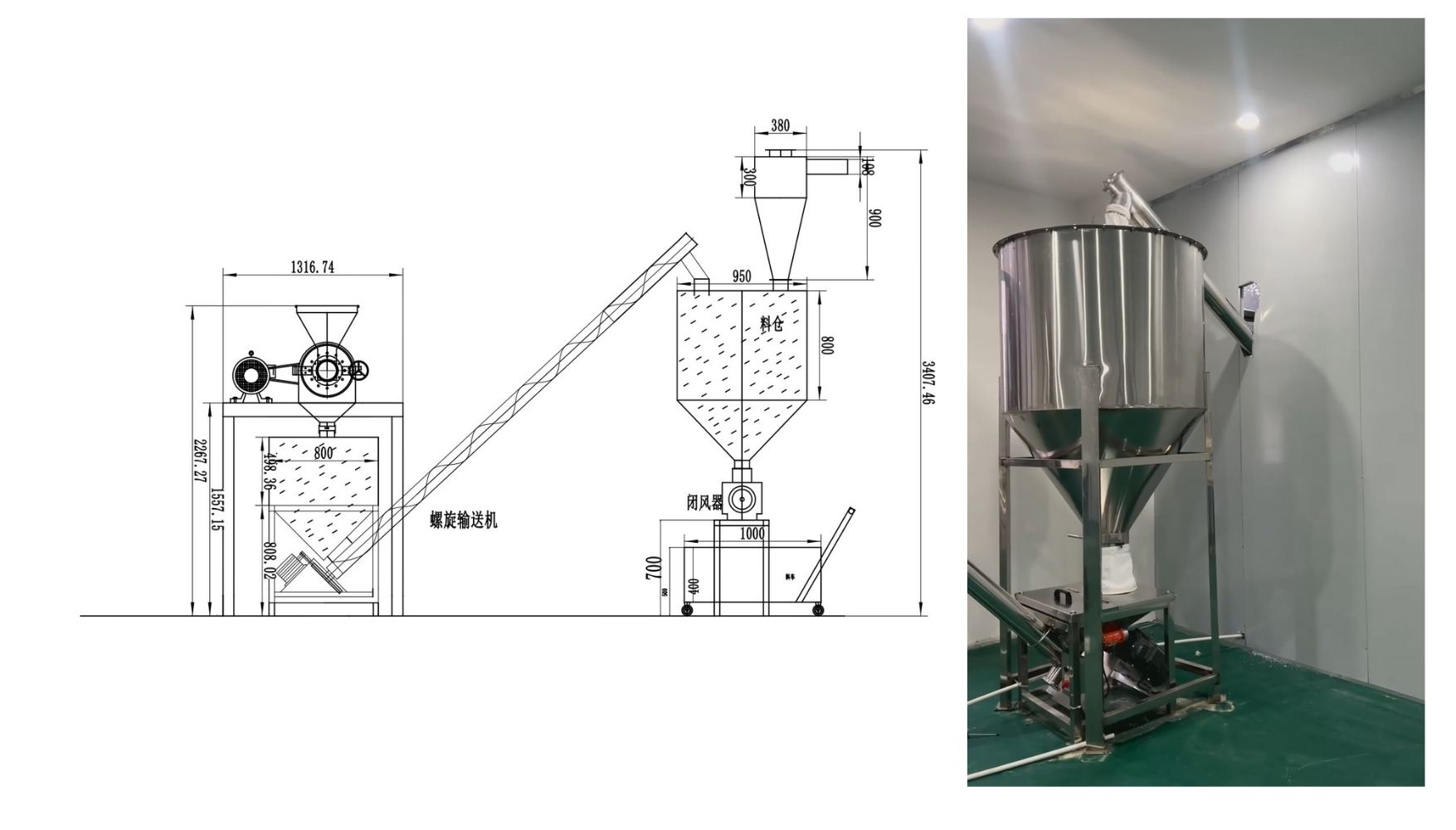

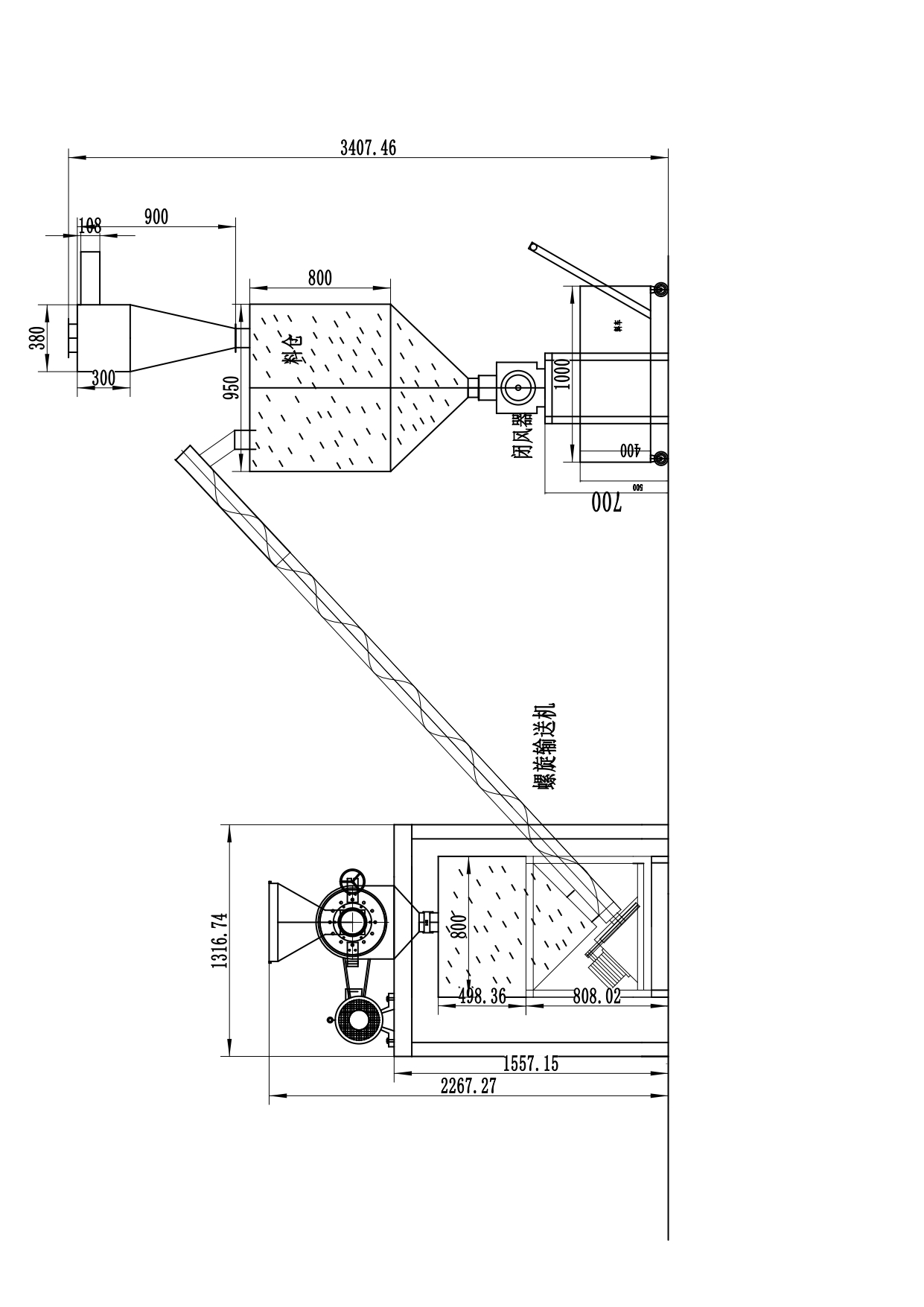

The Storage Silo is a critical component in powder processing production lines, serving as an intermediate storage vessel between material handling equipment. Typically positioned after bucket elevators or conveying systems, our silos provide temporary storage before materials proceed to mixing, packaging, or further processing stages. Constructed from high-quality stainless steel or carbon steel, our silos ensure reliable material storage while maintaining product quality and facilitating smooth production line operations.

Key Features

- Material Options: Available in 304/316 stainless steel for food-grade applications or carbon steel for cost-effective solutions

- Capacity Range: Customizable volume from 0.5m³ to 50m³ to meet various production requirements

- Discharge Design: Cone-bottom configuration with optimal angle for gravity-assisted material flow

- Integration Ready: Standard flange connections for easy integration with conveyors, elevators, and packaging equipment

- Safety Features: Level indicators, inspection ports, and pressure relief valves for safe operation

- Surface Finish: Polished interior surfaces for easy cleaning and material flow

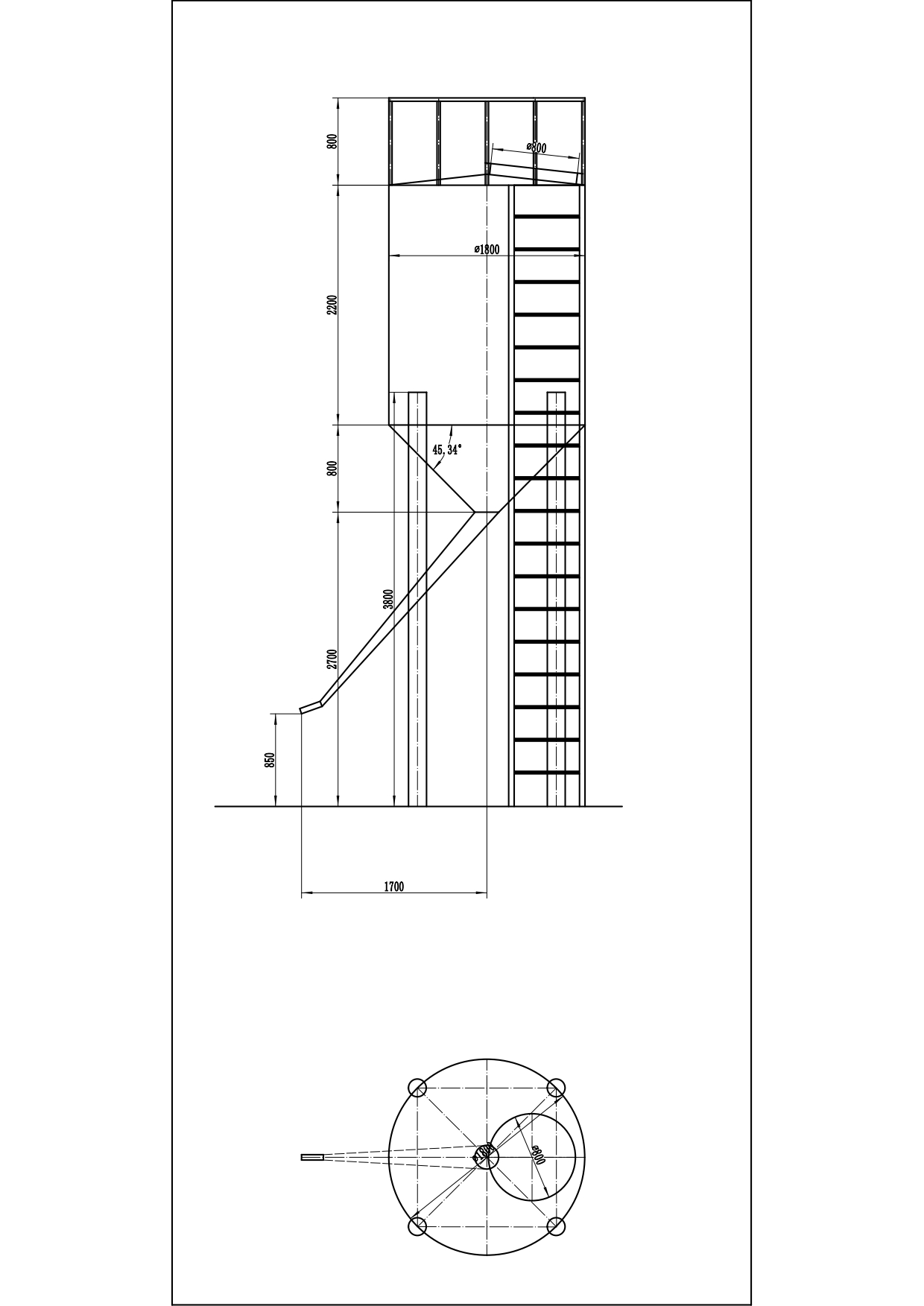

Technical Specifications

- Material: 304/316 stainless steel or carbon steel

- Capacity: 0.5m³ - 50m³ (customizable)

- Working Pressure: Atmospheric pressure

- Temperature Range: -20°C to +80°C

- Discharge Angle: 60° cone bottom

- Surface Finish: Ra ≤ 0.8μm (interior)

- Connection: Standard flange DN150-DN300

- Accessories: Level sensor, inspection port, manhole

Product Details

Our storage silos are engineered with precision to ensure optimal material storage and flow characteristics. Each silo is custom-designed based on material properties, capacity requirements, and integration needs.

Working Principle & Production Line Integration

In a typical production line workflow: Material Feeding → Grinding/Processing → Bucket Elevator → Storage Silo → Mixing/Packaging. The storage silo serves as a buffer vessel, receiving materials from bucket elevators or pneumatic conveyors through the top inlet. Materials are stored in the cylindrical chamber until needed for the next production stage. The cone-bottom design ensures first-in-first-out material flow, preventing segregation and maintaining product quality. When production continues, the discharge valve opens and materials flow by gravity to downstream equipment like mixers, packaging machines, or secondary processing units.

1V1 Custom Service

We provide professional 1V1 custom services, designing equipment technology according to customers' specific needs. Our engineering team has rich industry experience and can tailor the most suitable solutions for customers.

Scope of Application

Our storage silo is designed to serve a wide range of industries with diverse material processing needs. We provide comprehensive powder processing solutions that meet the specific requirements of each industry sector.

Company Strength Introduction

Zhengzhou PinChuang Machinery is a professional manufacturer specializing in customized powder processing solutions. With over 10 years of experience, we provide complete production lines, including pulverizers, mixers, elevators, dust collectors, and packaging machines.

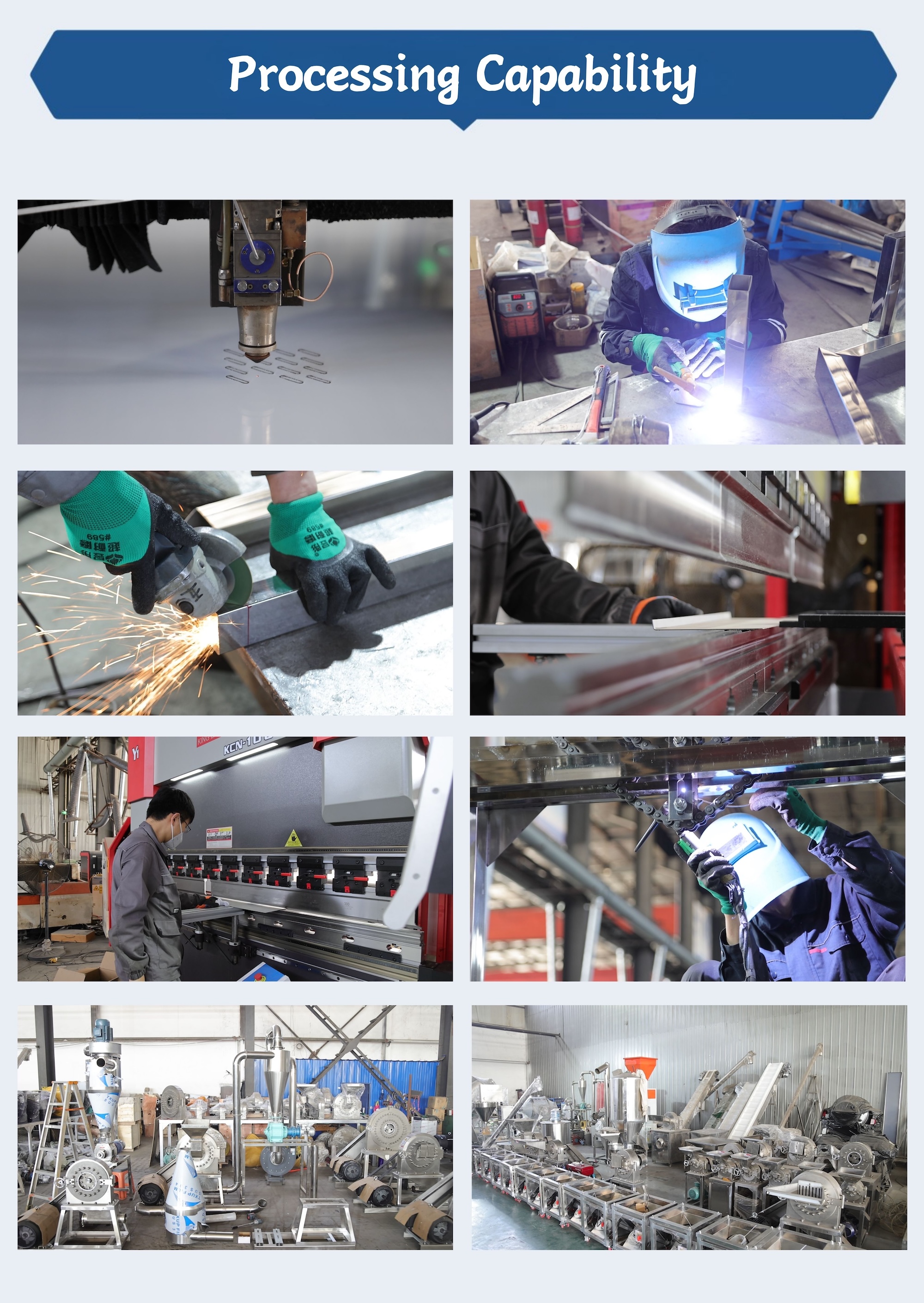

Our factory is located in Henan, China, covering more than 3,000 square meters, and equipped with advanced CNC cutting, welding, and polishing facilities. We serve industries such as food processing, herbal medicine, spices, and grain milling with efficient and durable machinery.

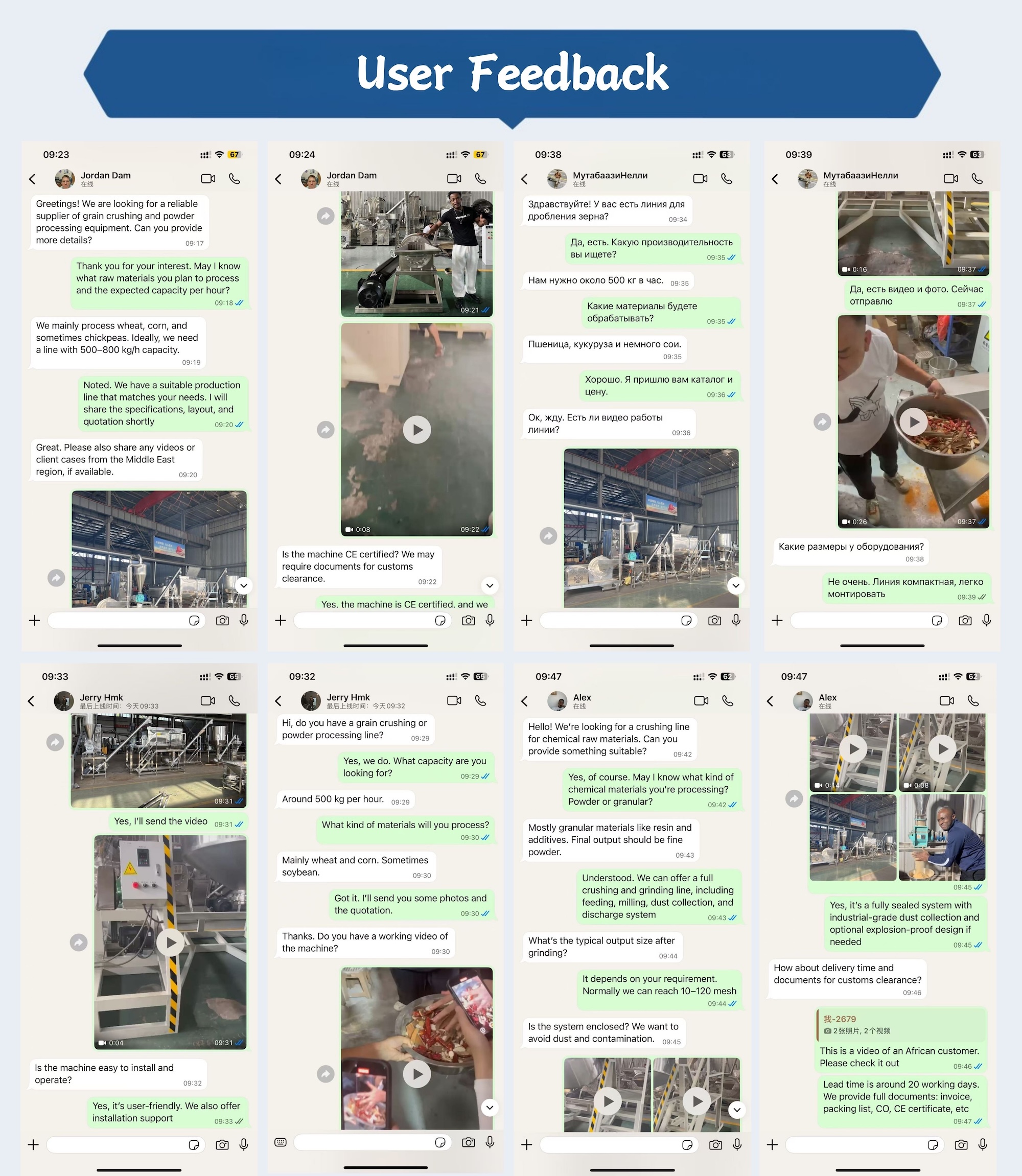

User Feedback Photos

Real feedback from customers on our products and services, demonstrating our professional standards and service quality.

Logistics & Equipment Installation and Debugging

We provide complete logistics and delivery services. Professional teams are responsible for equipment installation and debugging to ensure normal operation of equipment.

Company Processing Capability

We have advanced processing equipment and professional technical teams to provide customers with high-quality custom products.

Certificate Photos

We have multiple industry certifications and certificates to ensure product quality and service standards.