Sugar Grinding Machine: Efficient & Hygienic Solution for Food Processing

Equipped with dedicated dust collection and intelligent control systems, modern Sugar Grinding Machines solve traditional grinding challenges, becoming essential equipment for food processing enterprises seeking efficient and hygienic sugar processing solutions. These advanced systems deliver consistent particle size reduction while maintaining the highest standards of food safety and operational efficiency.

Advanced Grinding Technology

Precision Grinding Mechanism:

Utilizes high-speed impact and attrition grinding principles with specially designed grinding elements that minimize heat generation, preventing sugar crystallization changes and caramelization during the grinding process.Temperature Control Systems:

Integrated cooling mechanisms maintain optimal processing temperatures below 40°C, preserving sugar quality and preventing moisture absorption that can lead to caking and equipment fouling.Variable Particle Size Control:

Achieves precise particle size distribution from 20-200 mesh with interchangeable screens and adjustable grinding parameters, meeting diverse application requirements from confectionery to pharmaceutical industries.

Hygienic Design Features

Food-Grade Construction

- Stainless Steel Contact Surfaces: All product contact areas constructed from 304/316L stainless steel

- Sanitary Design Standards: Compliance with FDA, 3-A Sanitary, and EHEDG guidelines

- Smooth Surface Finish: Electropolished surfaces with Ra ≤ 0.8μm for easy cleaning

- Crevice-Free Design: Welded joints and rounded corners eliminate bacterial harbourage points

Contamination Prevention

- Positive Pressure Systems: Filtered air supply prevents external contamination

- Sealed Processing Environment: Enclosed grinding chamber with gasket-sealed access ports

- Material Isolation: Segregated product and mechanical zones prevent cross-contamination

- Hygienic Connections: Sanitary clamp connections for easy disassembly and cleaning

Dust Control & Collection

Advanced Dust Management

- Multi-Stage Filtration: Primary cyclone separation followed by high-efficiency bag filtration

- Pulse Cleaning System: Automated filter cleaning maintains consistent airflow and efficiency

- Explosion Prevention: Inert gas systems and explosion relief panels for safety

- Dust Recovery: Collected fine sugar particles returned to product stream

Environmental Compliance

- Emission Control: Achieves >99.5% dust capture efficiency meeting strict environmental standards

- Air Quality Monitoring: Continuous monitoring of workplace air quality parameters

- Noise Reduction: Sound attenuation systems for community-friendly operation

- Energy Recovery: Heat recovery from exhaust air for process heating applications

Product Applications

Confectionery Industry

- Powdered Sugar Production: Ultra-fine grinding for icing and dusting applications

- Chocolate Manufacturing: Precise particle size for smooth chocolate texture

- Candy Production: Consistent sugar powder for hard candy and gummy formulations

- Bakery Applications: Fine sugar powders for cake decoration and specialty baking

Pharmaceutical & Nutraceutical

- Tablet Manufacturing: Precise particle size for uniform tablet compression

- Coating Applications: Fine sugar powders for pharmaceutical coating processes

- Supplement Production: Sugar grinding for nutritional supplement formulations

- Medical Foods: Specialized sugar processing for medical nutrition products

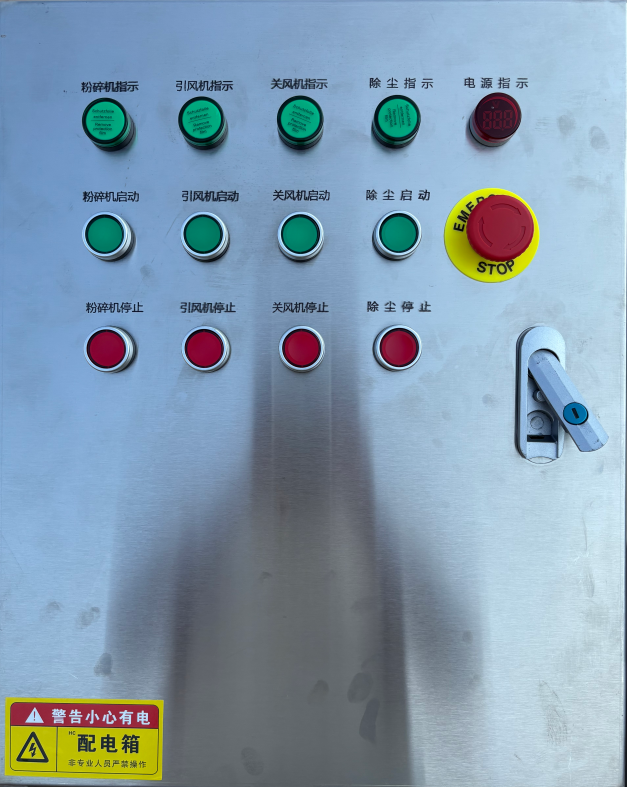

Process Control & Automation

Intelligent Control Systems

- PLC-Based Operation: Advanced programmable logic controller with touchscreen HMI

- Recipe Management: Storage and recall of grinding parameters for different products

- Process Monitoring: Real-time monitoring of temperature, pressure, and flow rates

- Data Logging: Comprehensive batch records for quality assurance and traceability

Quality Assurance Features

- Particle Size Analysis: In-line laser diffraction for continuous monitoring

- Metal Detection: Integrated metal detection systems for foreign object removal

- Weight Control: Precision weighing systems for accurate batch processing

- Statistical Process Control: Automated quality control with alarm systems

Maintenance & Reliability

Designed for Durability

- Heavy-Duty Construction: Robust frame design for continuous operation

- Wear-Resistant Components: Hardened grinding elements for extended service life

- Easy Access Design: Quick-release mechanisms for rapid maintenance access

- Modular Construction: Replaceable components minimize downtime

Preventive Maintenance

- Condition Monitoring: Vibration and temperature monitoring for predictive maintenance

- Lubrication Systems: Automated lubrication for critical bearing points

- Wear Monitoring: Grinding element wear detection and replacement alerts

- Service Support: Comprehensive maintenance training and technical support

Economic Benefits

Operational Efficiency

- High Throughput: Processing capacities from 100kg/hr to 2000kg/hr

- Energy Efficiency: Optimized grinding chambers reduce power consumption by up to 30%

- Reduced Waste: Precision grinding minimizes over-grinding and product loss

- Automated Operation: Minimal operator intervention reduces labor costs

Return on Investment

- Improved Product Quality: Consistent particle size distribution enhances product value

- Reduced Processing Time: High-efficiency grinding reduces cycle times

- Lower Maintenance Costs: Durable construction and predictive maintenance reduce downtime

- Regulatory Compliance: Hygienic design eliminates costly compliance issues

Scalability Options

- Laboratory Scale: 1-10 kg/hr for R&D and quality control applications

- Pilot Scale: 50-200 kg/hr for process development and small production

- Production Scale: 500-2000 kg/hr for commercial manufacturing operations

- Custom Solutions: Tailored designs for specific capacity and application requirements

Modern sugar grinding technology combines efficiency, hygiene, and reliability to meet the evolving needs of the food processing industry, providing manufacturers with the tools necessary to produce high-quality sugar powders while maintaining strict food safety standards.

Need More Information?

Our professional team will provide personalized recommendations

Send Email Inquiry WhatsApp Inquiry